7 Different Types of Table Saws & Their Uses (with Pictures)

-

- Last updated:

Choosing the right style of table saw will make your work faster, safer, and more efficient, whether the projects you have in mind are fine woodworking, DIY, or construction. You will find yourself returning to this versatile and practical piece of equipment time and time again.

Each type of table saw has its unique benefits and drawbacks, making them either more or less suitable to your needs. By the time you finish reading this guide, you’ll be able to decide which category of saws to research and purchase. Since they’re broadly separated into portable and stationary models, a wide range of table saw options are available to suit every budget, size, and power requirement.

In this article, we will introduce you to seven table saws that suit every job imaginable, from the smallest trim work to cutting whole boards to size.

The 7 Different Types of Table Saws & Their Uses

1. Mini Table Saw

As the most recent addition to the table saw family, mini table saws are a hobbyist’s dream come true. Their small, lightweight designs make them exceptionally portable, yet they retain the table saw’s ability to make accurate and precise straight cuts. Though their diminutive size makes them unsuitable for anything larger than detail work, their equally small price tags make them an attractive option for beginners. The Rockwell Blade Runner X2 is a great entry-level/hobbyist table saw at an affordable price.

Common uses: Arts and crafts, minor home repairs, trim and decorative woodwork, basic DIY projects

- Lightweight and easily portable

- Takes up very little space

- Inexpensive

- Easy to set up and operate

- Perfect for beginners

- Limited rip capacity

- Only suitable for small projects

2. Benchtop Table Saw

With more power and durability, benchtop saws offer an economical solution to small-scale sawing needs. While they’re still far from powerful enough to rip whole man-made boards to size, you can make essential home repairs in a flash. Equip your benchtop table saw with specially designed blades to cut metals and plastics, and it may become your go-to choice for weekend projects. The DeWalt DW745 10-inch Table Saw has a 20-inch rip capacity and a stellar reputation for dependability.

Common uses: Small furniture building (coffee tables, dog houses, chairs), minor construction projects (sizing and installation of small pipes), arts and crafts, decorative woodworking

- Lightweight and portable

- More powerful than a mini table saw

- Easy to set up and use

- Reasonably priced

- Small rip capacity limits project size

- Huge variation in quality of available product models

3. Compact Table Saw

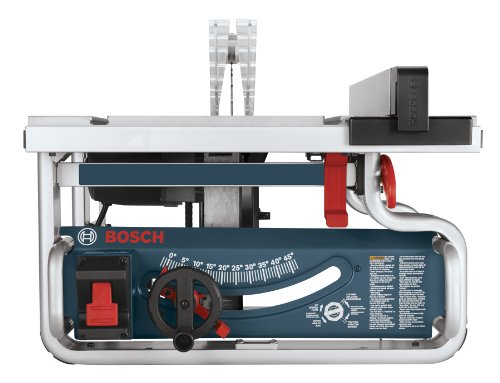

Larger and more powerful than a benchtop table saw, yet still lightweight and portable enough to use anywhere, compact table saws offer greater power and sturdier construction than their smaller counterparts. Often resembling miniaturized versions of cabinet table saws, they are a more expensive but longer-lasting option for small projects and home use. The Bosch GTS1031 has a one-handed carry handle for easy transport.

Common uses: In-house or on-site furniture building, small construction projects, small to medium DIY projects

- Large rip capacity for a portable saw

- Sturdy construction

- Designed to be longer-lasting

- Not great at handling hardwoods and pressure-treated lumber

- More expensive than previous options

4. Jobsite Table Saw

Common uses: Professional carpentry and construction, medium to large furniture and building projects, heavy-duty home improvement and DIY

- Rugged and long-lasting construction is made for everyday use

- Combines the versatility of portable and stationary saws

- Powerful enough to easily cut thick lumber, hardwoods, plastics, and metals

- Most expensive portable option

- Wide variation in quality among different product models

5. Contractor Table Saw

Originally intended as a more manageably sized alternative to cabinet-style table saws, contractor saws long held sway as the choice of professional woodworkers. In the push for new hardware technology of the past 20 years, however, smaller and more powerful portable saws have overshadowed this once-popular style. Still, it finds favor with dedicated hobbyists who appreciate its high power being available at reasonable prices. With a 52-inch rip capacity, the Delta 36-5052 is one of the most reliable and popular contractor saws on the market.

Common uses: Professional carpentry and construction, medium to large furniture and building projects, heavy-duty home improvement and DIY

- Professional-grade woodworking

- High-level decorative work and hobbyist projects

- Small, medium, or large home improvement projects

- Less powerful than any other stationary table saw

- Somewhat outdated

6. Hybrid Table Saw

Hybrid saws fall somewhere between the size and power of a contractor table saw and the updated technologies of cabinet table saws. However, hybrid saws can be confusing to categorize properly. In short, they provide the long-term reliability and low-vibration belt-drive motors of higher-priced cabinet saws at a more affordable cost but sacrifice their maximum rip capacity to do so. They’re the high-end saw of choice for anyone short of a professional woodworker or furniture maker. The Shop Fox W1819 is built to handle the spectrum of woodworking projects.

Common uses: Woodworking jobs of all shapes and sizes, construction jobs calling for detailed, precise cuts, large home repair projects

- Highest accuracy cuts due to low vibration

- Capable of handling even large furniture-making or construction jobs

- As powerful as a cabinet table saw but less expensive

- Significant financial investment

- Smaller rip capacity than a cabinet table saw

7. Cabinet Table Saw

The cabinet saw is the king of table saws. All other styles can only dream of achieving the cabinet table saw’s combination of accuracy, power, and colossal rip capacity. You’ll often see them as the centerpiece of professional woodworking shops, where they become the central hub of activity during every construction or furniture-making project. They’re big, expensive, and definitely not portable. Check out the Sawstop PCS175 for the end-all-be-all of cabinet table saws.

Common uses: Professional-quality woodworking, furniture making of all sizes, larger construction projects, milling boards to size, cuts requiring extreme accuracy and precision

- Most powerful table saw

- Largest rip capacity

- Greatest accuracy of cuts

- Suitable for any woodworking project

- Takes up a lot of space

- Heaviest of all table saws

- Most expensive saw for your shop

• You might also like: HOW MANY WATTS DOES A COFFEE MAKER USE? DO THEY CONSUME LOTS OF POWER?

Conclusion

The most important factor to consider in choosing a table saw for yourself is how big your projects will be. For decorative trim work and basic DIY projects, a smaller and more portable table saw will be a convenient and inexpensive solution. However, for larger-scale work on furniture or construction, you’ll need a larger and more powerful saw.

You might also be interested in: 6 Best Benchtop Milling Machines – Reviews & Buying Guide

See Also:

- Table Saw vs Miter Saw: What’s the Difference?

- Band Saw vs Table Saw: Which One to Choose?

- Table Saw vs Circular Saw: Which One Should You Choose?

Contents