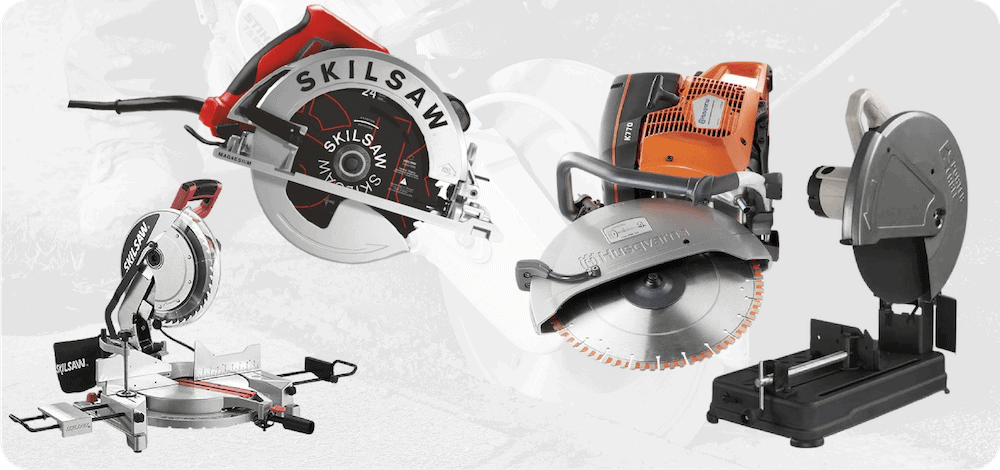

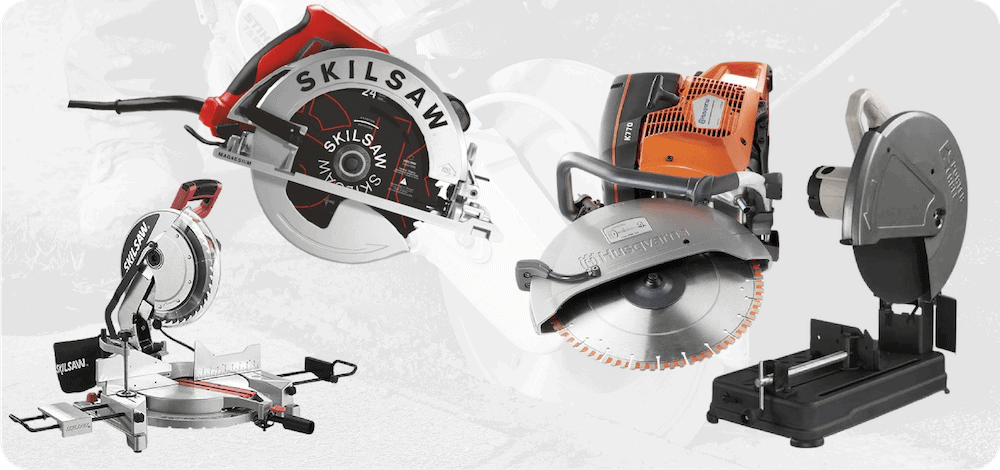

9 Different Types of Circular Saws & Their Uses (with Pictures)

-

- Last updated:

Circular saws are the invaluable bread and butter of the woodworking world. Economical, portable, and able to make anything from long rip cuts to quick-and-dirty miters and bevels, no carpenter ever wants to be caught without one.

But while we all agree circular saws are awesome, there’s more debate when it comes to the various subcategories. Some crafters are worm-drive partisans, while others back sidewinders. Some refuse to use blades that aren’t made of carbide, and some don’t think blades should even have teeth.

Still others don’t know there are different types of circular saws at all. To help them out, and to help you choose what kind of circular saw you need for your dream project, we’ve put together a list of the nine kinds of circular saw you need to know.

The 9 Types of Circular Saws

1. Sidewinder Circular Saws

Sidewinders are also known as in-line circular saws, and what most people probably think of when they picture a circular saw. To keep these saws small and portable, the motor is mounted to the left of the blade, directly turning the shaft that turns it around.

Without many moving parts, sidewinder saws make efficient use of energy, allowing the blade to turn quickly. They almost always use corded electricity or a lithium-ion battery as their power source.

Use it for: Rip cuts, plywood, soft lumber, vertical cuts, overhead cuts

- Portable

- Fast blade

- Don’t need oil

- Rip fence not included

- Less power

2. Worm Drive Circular Saws

The conventional alternative to sidewinder saws, worm drives have a motor mounted behind the blade, connected to it by gears. This results in less speed, but more torque. Worm drive partisans like them for their increased power and durability, and for the improved sightlines that result from a thinner, deeper saw.

Use it for: Longer cross and miter cuts, plunge cuts

- Increased torque

- Better sightlines

- Heavy

- Slower

- Need oil

3. Hypoid Circular Saws

Hypoids are the dark horse in the contest between sidewinders and worm drives. Similar to worm drives, they have a motor mounted behind the blade. What sets them apart from a worm drive saw is almost entirely mechanical — hypoid saws transmit power to the blade using beveled gears that don’t intersect.

In practice, the main difference is that the engines on hypoid saws are enclosed and don’t need to be oiled. The beveled gears also make them quieter than worm drive saws, though the power is about the same.

Use it for: Cutting hard or wet lumber

- Powerful cuts

- Quiet

- Doesn’t need oil

- Heavy

- Motor wears out sooner than other saws

4. Abrasive Circular Saws

Abrasive saws are used for cutting materials that are harder than wood (that’s most of them). Since teeth bounce off most harder substances, abrasive saws — also called chop saws — do away with teeth entirely, opting instead for a flat blade that resembles a pizza cutter.

Abrasive saws can be handheld, or fixed to a table or radial arm. They’re effective at cutting tile, pipe, concrete, and asphalt. Blades tend to be made of diamond or cubic boron nitride.

Use it for: Any workpiece harder than wood

- Lots of control

- Used for materials other than wood

- Generates extreme heat

5. Biscuit Joiners

Biscuit joiners use a circular saw as one part of a complex mechanism to join two workpieces together without any visible nail holes. The saw blade cuts a slit in each board, and a third piece of wood called a “biscuit” is glued inside both of them. With enough woodworking skills, this could probably be done without a specialty tool, but it’s still nice to have.

Use it for: Bonding pieces of wood together without visible holes

- Attaches two pieces of wood cleanly

- Only good for one purpose

6. Miter Saws

Miter saws are easier to use and safer than portable circular saws, though they tend to be more expensive. They’re capable of making crosscuts, miter cuts, bevel cuts, or compound cuts in record time.

Use it for: Quickly cutting lots of lumber to size

- Easy to use

- Four types of cuts

- Safe

- Expensive

7. Concrete Circular Saws / Grinders

Concrete saws, also known as slab saws, are an alternative to toothless abrasive saws for cutting through hard, high-resistance materials like concrete and metal. Instead of forgoing teeth entirely, concrete saws use a special arrangement of teeth made out of industrial diamond or something almost as hard.

They’re able to cut while clearing away dust and debris, but the blade quickly gets very hot. Make sure to regularly apply coolant, and take frequent breaks. The concrete will still be there when you get back.

Use it for: Cutting concrete and masonry

- Cuts hard materials

- Runs on a variety of fuel

- Expensive

- Overheats easily

- Heavy

8. Table Saws

A table saw consists of a circular saw blade connected to a motor, mounted inside a slot on a table or workbench so that only a bit of the blade is visible. Instead of pushing the blade across the workpiece, you hold the workpiece and move it across the blade. You’ll set a fence in place to ensure the board stays straight.

Table saws make crosscutting and ripping boards far easier for the novice than handheld sidewinder or worm-drive saws, but since they’re rooted in place, they sacrifice a lot of versatility. Bevel cuts are also much more of a pain.

Use it for: Crosscuts and rips in all hardnesses of wood

You can cut metal with any circular saw with a blade that’s good for cutting metal, but some saws are explicitly made for doing just that. Metal is more rigid than wood and is tougher to cut. You also have to worry about sparks from the metal-on-metal contact, and metal shards that are being thrown from the blade. Saws that are made for cutting metal are designed in a way that offers better protection from those sparks and shards. These saws generally cut more slowly than wood-cutting saws because the blades are quite a bit smaller than those on standard circular saws. Use it for: Cutting any type of metal The principles behind circular saws couldn’t be simpler. They’re one of the six simple machines with teeth, and sometimes without even those. We hope we’ve given you a sense of the amazing range of applications you can use this simple concept for. When the time comes to buy your next saw, you’ll now have a better sense of which one to choose. Have fun! See Also: Featured Image Credit: Capt. Holly Hess, U.S. Air Force Contents

9. Metal Cutting Circular Saws