How Does a Scroll Saw Work? (with Pictures)

-

- Last updated:

A scroll saw is an extremely useful tool for woodworkers and artisans. If you are considering purchasing a scroll saw but not sure if you will benefit from all that it has to offer, we will help try and clear up this dilemma for you. A scroll saw has a very specific function and, if used correctly, can produce incredible works of art.

What Is a Scroll Saw?

A scroll saw is very similar to a band saw in that you push the wood up against the blade to get the desired cut that you need. The difference you will find between the band saw and the scroll saw is the blade type. The band saw has a blade on a continuous loop, and the scroll saw has a reciprocating blade. The reciprocating blade allows for a much more precise cut.

Blade Types

There are several types of blades available to use on a scroll saw.Standard Tooth

On a standard tooth blade, the teeth are evenly spaced and are all the same size.

Wood blades have larger teeth with greater space between them to clear the sawdust as you cut.

On a metal blade, the teeth are smaller and closer together. These blades are also much noisier.

Skip Tooth

The next major type of blade is the skip-tooth blade. As the name would suggest, there is a skip or space between the teeth. It has half as many teeth as the standard blade. The wider space between the teeth keeps the blade cooler and makes it an especially good blade for beginners to use.

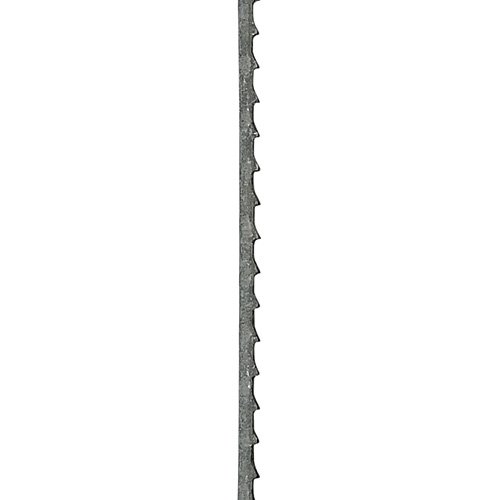

Specialty Blades

There are other specialty blades available like the spiral blade (pictured below) but most people will be fine using these two types.

What Is It Used For?

Scroll saws are used for intricate cuts. This type of work would be something like an elaborate sign, a wooden toy, or jigsaw puzzle, or maybe a spindle you would see on a staircase. Think intricate patterns, slower work, severe angles, and circular patterns; the scroll saw will lead the way when it comes to these applications. Most scroll saws are going to work with a foot pedal so that the user can employ both hands to guide the wood that they are working on.

With this saw, you can turn the wood to create wavy lines, right-angle turns, zigzag patterns, and more. You can also make interior cuts.

Interior Cuts

To make an interior cut you’ll need to drill a tiny hole in the wood, large enough for the saw blade to fit through. Drill the hole as close to perfectly vertical as possible. Unhook the bottom end of the blade from the motor, put it through the hole in the wood, back through the table of the saw, and reattach it to the motor. Make sure you still have good tension, then proceed to cut whatever pattern you’re following – a circle, a spiral design, a maze pattern, etc.

- Can be used for internal cuts

- Very smooth cuts

- Useful for detailed patterns and designs

- Does not take up a lot of space

- Ability to control the saw with the use of a foot pedal

- Can cut metal, wood, or plastic with the change of a blade

- Not a very versatile saw

- More for woodworking and craftsman and not construction or demolition

- Not a portable saw

Things to Consider When Purchasing a Scroll Saw

If you decide that a scroll saw is precisely what you need to add to your workshop, here are a few things you will want to consider before making your final purchase.

- Speed: Most scroll saws will have a variable speed option. It is nice to be able to tailor your work and your skill to the speed of the saw. If you are a beginner, you can set the scroll saw on low and learn to control things before turning it up.

- Size: If you are going to be cutting very thin wood or metal or plastic, the size of the saw will not matter much. However, if you plan on cutting something 10 or 20 inches thick, make sure the scroll saw you purchased could accommodate this. You may see the size of the scroll saw referred to as throat size.

- Dust Collection: Especially when cutting a very detailed or intricate pattern, visibility is critical. If you can’t see what you are doing, there is no way that you can cut things well. Some dust collection systems will just blow dust away, and others will collect the dust as you cut. Either option is fine as long as it works well.

- Blade Change and Tensioning: There will be some adjustments to blades while cutting. You may have to make the blade tighter, or you may need to change it out altogether. The better scroll saws will allow you to do this without having to use a tool. Sometimes in the middle of a project, you will need a new blade, and it is a hassle to get the took box out just to switch a blade. If you can find a scroll saw with tool-less blade change and tensioning options, we highly recommend doing so.

- Price: Like any other saw on the market, a scroll saw is going to vary widely in price. Some lower-end saws will be priced around $100, and others will make it into the thousands. Be realistic about what you need the saw for and how often you will use it.

Conclusion

When it comes down to whether you need a scroll saw, you need to consider the details of the final product. If you are making a 48-piece wooden jigsaw puzzle, cutting with a band saw or jigsaw would be a bit of a nightmare. If, however, you are just trying to cut a few missing pieces of molding for your home, you may not need a scroll saw. Think of a scroll saw as a mix between a power saw and an Exacto knife. You will have the convenience of a power tool on your side with the precision of a human hand.

Related Reads:

- How To Clean a Paint Sprayer After Use

- How To Paint Spray Your Car Like a Pro

- How To Use a Paint Sprayer With an Air Compressor (6 Easy Steps)

Contents