49 Different Types of Saws and Their Uses – Which is Right For You?

-

- Last updated:

To give you a head start on figuring out which saws can be used for which types of jobs, we’ve put together this guide to 49 styles of saws and their uses. By examining their qualities and features, you’ll better understand why each saw was created and which project it’s meant for.

Whether a small home woodworking project or a larger construction job, you’ll be fully prepared to choose the right saw.

The 49 Different Types of Saws

We’ve broken down the saws into the types of hand saws and types of electric saws. Keep reading to learn more, or click below to jump ahead:

The 20 Types of Hand Saws:

While more handymen are turning to power tools for their convenience and accuracy, hand saws give you a feel for your materials that can increase accuracy and encourage the production of a sophisticated finished product. They’re the go-to tool for small projects and a pleasure to use.

1. Hand saw

A basic hand saw is a staple for home toolboxes. Hand saws have long, flexible blades with teeth slightly offset to allow for continuous sawing.

Depending on the type of job it’s intended for, a hand saw will have different types of teeth:

- Rip teeth are for cutting with the grain, perfect for sawing boards to width

- Crosscut teeth can saw across woodgrain without tearing the fibers and are particularly useful for cutting joints

- Japanese crosscut teeth perform the same function but make a narrower cut

- Dual-purpose teeth are symmetrical and can be used for both cutting with and across the grain

2. Hacksaw

With hardened teeth fused to a flexible steel back, hacksaws are more suited for metalworking than woodworking. They’re the ideal saw for cutting thick metals, such as bars and tubes.

3. Crosscut saw

Known as a lumberjack saw, two-person crosscut saws have a leading edge that leans back slightly and is sharpened at an angle to form a precise edge and tip. Each tooth acts like a knife to score the wood, allowing sawdust to fall out as the blade passes. They’re the right choice for cutting joints or sawing a plank to length.

4. Pruning saw

Sometimes you can find pruning saws mounted to the end of poles for working on tree limbs, but as a hand tool, it’s great for reaching low-hanging branches or a line of dense vines. Designed specifically for use in managing trees and shrubs, pruning saws have many more teeth per inch than comparably sized saws. With a curved handle and blade, they can make quick work of trimming branches even in hard-to-reach areas.

5. Bow saw

Narrow blades are fitted to a small, lightweight frame in the bow saw. This makes them ideally suited to making curved cuts, as they can be turned 360 degrees to move frames out of the way. At 8 to 12 inches long, they’re hardy enough to saw through thick sections of solid wood.

6. Folding saw

Exceptionally useful for camping and backpacking, folding saws also see use around the house as convenient and space-saving options for pruning. Lightweight and compact, the best folding saws feature razor teeth that make short work of small branches.

- Pruning style, where the blade folds down into the handle. They can easily be carried in a belt-mounted holster.

- Folding bow style, which folds out from a collapsed position and locks into place. You can apply more force to these, and they’re easier to store in a backpack.

Folding saws are often called “camping saws,” but it’s important to note that not all folding saws are necessarily for camping, where space and weight are premium assets. If you’re looking for a camping saw, it should be portable and foldable. They’re useful for trimming trees and dividing firewood at your campsite, and we’re big fans of models that come with a sheath and non-slip grip.

7. Japanese saw

Japan has a robust tradition of developing specialized saws for every job imaginable. The common characteristic of all Japanese saws is that they cut on the pull stroke rather than the push that is common in Western blades. This means the blades can be made much thinner, allowing for virtually no tearing of the grain.

- Related Read: 10 Best Japanese Saws

8. Fret saw

The fret saw takes its name from the French word for lattice, “freter.” As a variation on the bow saw designed for cutting tight curves, a fret saw is appropriate for very intricate work. Their fragile blades are equipped with up to 32 teeth per inch, making them more accurate and more fragile. The name “fret saw” is sometimes used interchangeably with “scroll saw.”

9. Back saw

With relatively thin blades and small, finely set teeth, back saws can be used for precise work. A heavy strip of brass or steel wrapped over the top edge of the blade helps keep the blade straight, and the extra weight makes for easier cutting with less force applied. They are available in various lengths and handle styles, and they are referred to as tenon saws, dovetail saws, bead saws, and blitz saws.

10. Veneer saw

Veneer saws are for small, fast work. Their blade size gives them a minimal range, but within that range, they can work quickly and deliver very smooth results. Just make sure that you keep the teeth clean of debris. These saws can cut square-edged wood perfect for butt-joining matched veneers. Their reversible double-edged blades have fine teeth with no set.

11. Coping saw

Like the fret saw, the blades of the coping saw are held under tension by their metal frames and usually measure 6 inches long. They’re most useful for cutting curves in solid wood.

Because of how narrow the blades are (with 15 to 17 teeth per inch), coping saws cannot be sharpened and must be replaced when dull.

12. Keyhole saw

With a dagger-like point on the front of the blade, the keyhole saw – also called a pad saw, jab saw, or drywall saw – is used for cutting small, awkward shapes. Available with either a fixed or a retractable blade, they can make comparable cuts to the more popular electric jigsaw.

13. Wallboard saw

Since they’re specifically designed for cutting drywall, wallboard saws have teeth on both sides of a long, slender blade. A pointed tip allows for piercing cuts without drilling a pilot hole. Look for hardened or tempered blades to extend the lifespan of these hard-working saws.

14. Bone saw

Also known as a “butcher’s saw,” handheld bone saws have a similar design to the common hacksaw. Unsurprisingly, they are used for cutting through bones—most commonly by deer and other big game hunters. Look for all stainless-steel construction to prevent corrosion from animal blood.

15. Rip Cut Saw

This is an all-purpose woodworking saw that cuts with the wood grain, as opposed to crosscut saws that cut across the grain. Intended for rougher cuts and board sizing, the tooth edge is flat and carves out material with each push or pull, almost like a chisel. We like rip cut saws with a tapered end, as it reduces the friction you’ll experience while cutting.

16. Wire Saw

A favorite of survivalists and ultralight backpackers, wire saws are similar to reciprocating or band saws in their use of abrasion to cut wood rather than saw teeth. Handheld models are extremely lightweight but can take a long time and a lot of effort to complete even minor cuts. Look for models that have comfortable handles, or else your fingers will take a real beating.

17. Razor Saw

Favored by hobbyists and model train enthusiasts, the razor saw features finely pitched crosscut teeth that can make clean cuts in very soft woods used for model trains, planes, and boats. Unlike other members of the backsaw family, razor saws are often used to cut plastics and soft metals, as well as soft woods.

18. Carcass Saw

Referring to the framework carcass of a cabinet (not an animal), the carcass saw is remarkably similar to a tenon saw. Their stiff blades make them useful for precise cuts across wood grain thanks to their crosscut filed teeth. It’s a particularly specialized saw meant for more minor work than a tenon saw can handle accurately.

19. Pocket chainsaw

Take the chain off a standard gas-powered chainsaw, split it at one point, and add handles at both ends, and you have the basics of a pocket chainsaw. Like the wire saw, it’s a favorite of survivalists and backpackers thanks to its lightweight and compact design. They’re slightly heavier than wire saws but cut using teeth rather than friction— making them faster and easier to use.

20. Manual pole saw

This beast of convenience is a folding or pruning saw on the end of a long stick. It allows you to reach high places for light to medium-duty branch and brush cutting. The manual pole saw will give you a solid workout. Most people are now investing in gas or electric pole saws.

The 29 Types of Power Saws:

Power tools have led the way in building technology, making projects faster and easier to accomplish with minimal strain and effort. From tabletop to battery-powered, electric saws can make even the largest projects quicker and easier. The following 29 types of saws will keep you covered from the most intricate to the heaviest jobs.

21. Chainsaw

Property owners with a lot of trees probably have a chainsaw in the shed. Since the development of the first industrial chain saw in 1918, they’ve been used for felling trees of all sizes. Chainsaws with electric motors can be powered by a battery or a power cord and tend to vibrate less than gasoline-powered models. This makes them a popular choice for reducing fatigue on jobs that require a long duration of chain saw work.

22. Miter saw

Miter saws are designed for making angled cuts. A miter is a joint cut between two pieces of wood made by cutting equally angled surfaces at the end of both pieces. Miter saws are equipped with boxes that guide the angles of these cuts, making the production of perfect 45-degree angle cuts quick and easy. They’re an indispensable tool for cutting molding and trimming.

23. Circular saw

A circular saw is the power tool version of the hand saw. Portable circular saws are one of the most convenient ways to bring the utility of a table saw to work on-site. They allow for ripping and crosscutting wood and have long been a standby for carpenters and construction workers because of their lightweight and portability.

By changing to different blade types, you can easily use a circular saw for metal, stone, or ceramics.

24. Table saw

The centerpiece of any well-outfitted woodshop as well as a fixture on many construction and remodeling job sites, table saws know no equal in the power saw world. Consisting of a circular saw blade powered by an electric motor and featuring stable guides, they provide the fastest and most accurate way to make repeated cuts.

Types of table saw

- Cabinet-style table saws are the most powerful and accurate cutting option available, as well as the heaviest and most expensive.

- Hybrid saws are heavier than a contractor saw but lighter than a cabinet. They’re built to look and feel like a cabinet saw but compete more in the price range of a high-end contractor saw.

- Contractor table saws are large, powerful, heavy, and usually mounted on a base with wheels. They’re the closest you can get to the power and accuracy of a cabinet-style saw while still being able to transport it to a job site.

- Jobsite table saws are lightweight yet robust and may be our favorite option for a portable sawing solution. They’re well-equipped enough to handle larger or tougher jobs but also not so expensive as to be out of the budget of DIY enthusiasts.

- Portable table saws, also known as “benchtop” saws, are exceptionally lightweight and can often be carried in one hand. They’re inexpensive and reasonably powerful but often lack the greater accuracy promised by heavier saws.

25. Jigsaw

Designed to cut curves and details, the jigsaw has a thin blade that can be tracked around a cutout, so you get precisely the design you want. Also known as a “saber saw,” jigsaws are versatile workhorse tools. They’re equally capable of making straight and curved cuts, and their lightweight construction makes them most suitable for thin and man-made boards. They’re comfortable to use and relatively quiet and make a good first investment for a small home woodworking setup.

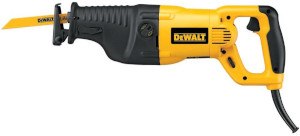

26. Reciprocating saw

Most often used for heavy construction jobs, reciprocating saws take the design of a jigsaw and orient it onto a handle that allows for vertical work. They’re especially useful in cutting drywall when accuracy is not a concern. Technically, “reciprocating saw” can refer to any blade that cuts with a back-and-forth motion but is most often understood to mean this saw used in construction.

27. Band saw

A band saw is kind of like a jigsaw connected to a table. Band saw blades are a continuous metal loop driven over two or three wheels. Unlike table saws, there is no danger of kickback in using a band saw. While it may not rip or crosscut as cleanly as a radial arm saw, its safety has made it a popular choice among cautious woodworkers. Also, band saws run relatively quietly and can make a good addition to any workshop in a quiet neighborhood.

What does a band saw blade look like?

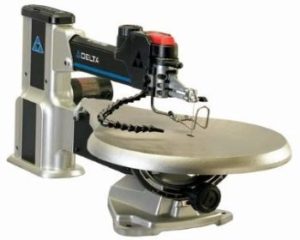

28. Scroll Saw

Used for cutting precise, intricate curves in almost any material, scroll saws have fine blades and variable operating speeds that make them perfectly suited for delicate work. The name of this saw comes from its traditional use in making scrollwork or wooden ornaments that featured waves and curls.

A unique feature of scroll saw blades

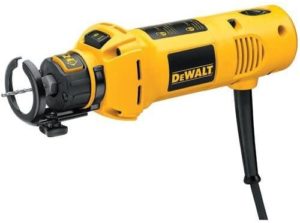

29. Rotary Saw

Although it was designed to make drywall cut-outs without a pilot hole, the rotating blade of this spiral-cut rotary saw quickly became popular in fire and rescue and medical contexts. For home or professional use, they’re still most commonly used for clean and accurate drywall work.

30. Gas or Electric Pole Saw

Also known as a “pole chainsaw” or “pole pruner,” the pole saw helps trim branches in hard-to-reach areas that would be unsafe to climb to while holding a chainsaw. Depending on the model, they can extend anywhere from 8 to 15 feet long.

31. Chop Saw

These stationary saws only move up and down, differentiating them from the miter saw that can make angled cuts. Mostly, you’ll find specialized chop saws in metal shops, as woodworkers will prefer the versatility of miter saws to the extreme vertical precision and power of a chop saw.

32. Flooring Saw

Designed specifically to allow you to cut flooring at the same site as your installation, flooring saws combine some of the capabilities of miter and table saws in a portable package. Thick rubber feet stabilize the saws while preventing damage to your newly installed flooring. They’re excellent for saving time and effort during flooring jobs but tend to be less accurate than a dedicated table saw.

33. Track Saw

Also known as a plunge saw, the track saw is a hyper-specialized version of a handheld circular saw. They run on a guide rail during operation, allowing for long and accurate cuts at a pre-determined depth. Some woodworkers favor them over circular saws thanks to their ability to reduce splintering and tear-out, making for a more polished final product.

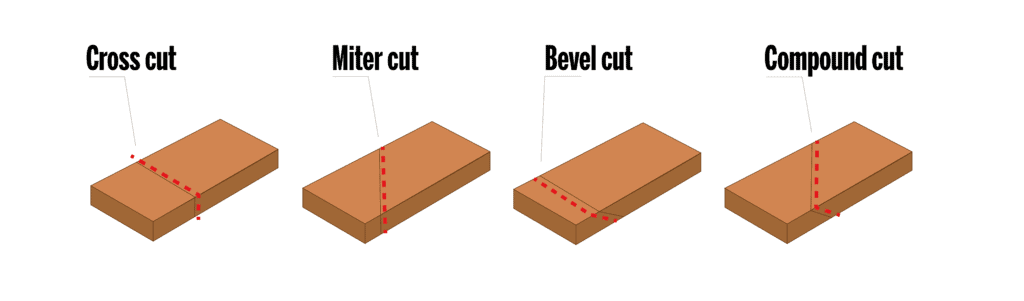

34. Compound Miter Saw

Used for making crosscuts, miters, and bevels by pulling a mounted circular blade downward, these stationary compound miter saws see frequent use in cutting trim. As opposed to a traditional miter saw, compound miter saws can tilt the head and blade at an angle to the workpiece, allowing for the addition of bevel cuts.

Types of cuts you can make with a compound miter saw

35. Masonry Saw

Variously named as a concrete saw, road saw, slab saw, or masonry saw, a diamond saw blade is necessary for the heavy-duty work these saws encounter. The most common varieties are handheld and resemble a circular saw, but rarely you’ll also find stationary chop saws. Because of the added friction experienced when cutting stone, many masonry saws will use water to cool the blade and reduce airborne dust.

36. Radial Arm Saw

As precursors to powered miter saws, these saws operate via a circular saw mounted on a movable horizontal arm. While they were considered high technology in the 1920s, by the 1970s, miter saws had begun to replace them due to the radial arm saw’s reputation for being dangerous to operate. Though still manufactured today, they’ve fallen out of favor compared to the more affordable portable miter saws.

37. Tile Saw

Integrating a water reservoir or distribution system into a small, mounted circular saw blade, wet tile saws make it easy to cut tile quickly and accurately to whatever measurement you need. Their ability to leave smooth, clean edges makes them the choice of professional tile setters, but their utility is limited outside of this application.

38. Oscillating Saw

Given the moniker of “Multi-Tool” by home DIY enthusiasts and professional remodelers alike, the oscillating saw is a lightweight and easy-to-use tool that excels in small spaces and tight corners. Various blades can be used to make it suitable for cutting through wood, metal, plastic, drywall, tile, and cement. It’s an excellent choice for smaller jobs but not appropriate for making accurate longer cuts.

39. Panel Saw

As a more specialized version of a table saw, the panel saw does just one thing: cut large sheets to size. They’re one of the biggest pieces of woodworking equipment anyone is likely to own and are rarely found outside of professional woodshops or cabinetry operations.

40. Cold Saw

Circular saws that are designed specifically for use in cutting metal are called cold saws, and they come in handheld and stationary models. Using a slower rotational speed and toothed blades made of thermal-resistant materials that allow them to stay cool, they are often used by sheet metal roofers.

41. Abrasive Saw

Using an abrasive disk rather than a toothed saw wheel, abrasive saws are available in handheld, tabletop, and walk-behind models. They specialize in grinding through hard materials like concrete and metal and are versatile tools for heavy-duty construction and demolition job sites.

42. Chain Beam Saw

Resembling a combination of a handheld circular saw and a downward-mounted chainsaw, the chain beam saw is specifically designed to make the work of timber framers and log builders faster and more efficient. They are quite expensive but offer unparalleled ease and accuracy for cutting big wooden beams.

43. Straight Flush Saw

This relative newcomer to the handheld saw market offers a specialized take on the classic circular saw; the straight flush saw allows for cuts directly adjacent to posts, studs, headers, and more. A recessed mounting point for the circular saw blade allows for this zero-clearance cutting style, often eliminating the need for using a reciprocating type of saw to clean up after a circular saw.

44. Toe-kick Saw

It’s hard to get much more niche than the handheld toe-kick saw, which is a small, flush-cutting circular saw that lets you cut under the toe-kick panels of cabinets so you can remove the flooring without removing the cabinet. They’re so specific that it may be more efficient to rent one rather than buy one.

45. Diamond Blade Wall Cutter/Slotter

Used for cutting narrow grooves in walls made of hard materials, these “wall chasers” are most often used for laying electrical cables. Wall cutters are equipped with abrasive discs capable of grinding through concrete and metal.

46. Jamb Saw

Sometimes called an “undercut saw,” the jamb saw is another hyper-specialized tool used for cutting out a small section of door jamb or molding. That way, you can lay flooring flush with the wall rather than the jamb or molding. It’s another type of saw that’s often better to rent than to own.

47. Biscuit Joiner

As part saw and part gluing box, a biscuit joiner can make edge-to-edge or perpendicular joints. A circular saw blade cuts a hole in opposite edges of two pieces of wood, where a wooden “biscuit” is covered with glue and inserted before clamping the boards together. The resulting joints are typically as strong as mortise and tenon joints.

48. Domino Joiner

As a modified version of the biscuit joiner produced by power tool legend Festool, the domino joiner cuts mortises to be filled with proprietary Festool brand tenons. They allow for quick joinery in commercial carpentry and produce a stronger joint than a biscuit joiner. However, they are more expensive and produce a lot of noise and dust.

49. Electric Hand Saw

We saved the most ridiculous type of saw for last—the electric hand saw. This virtually worthless saw offers all the inconvenience of a hand saw with none of the results. There isn’t any conceivable job that couldn’t be handled better by one of the previous hand or power tools. It’s nice to know that it exists, but we really can’t think of a reason for it.

Conclusion

That’s a wrap on our comprehensive look at the types of saws currently available and in use today. With the help of the experts, we’ve covered almost every kind of saw. Do you think we missed one? Send us a message and let us know!

See Also:

- Kobalt vs DeWalt: Which Power Tool Brand is Better

- 5 Best Vertical Panel Saws

- What is a Transmission Flush (And Do I Need One)?

- 13 Woodworking Tools to Get You Started

Contents